Penerangan Ringkas Produk:

Garis Penuh Automatik Pengeluaran Tisu Pocket ini merangkumi satu set Mesin Penyusunan Tisu Pocket dengan pengiraan automatik dan pemindahan automatik, dengan cetakan warna dan emboss adalah pilihan, satu set Mesin Pakatan Penuh Automatik Tisu Pocket, satu set Mesin Pakatan Luar Bar Penuh Automatik untuk Tisu Pocket.

Perincian Penerangan Produk:

I. WD-HT-210-V Mesin Tisu Pocket / Mini Jenis Tisu Muka dengan pemindahan automatik.

Ciri-ciri Utama:

1. Mesin ini direka baru oleh syarikat kami dengan teknologi canggih untuk memastikan mesin dengan kebolehpercayaan keseluruhan dan kestabilan operasi.

2. Tidak perlu membuat sebarang perubahan pada mesin bungkusan, mesin ini boleh disambungkan dengannya sebagai garis pengeluaran penuh automatik, menjalankan secara serentak dengan mesin bungkusan.

3. Keluarkan bilah dari saluran untuk memisahkan kertas tisu di bawah model mesin laju tinggi untuk pemisahan kertas tisu. Dipisahkan oleh bilah, rol lipatan kertas menarik keluar kertas tisu dilipat satu demi satu daripada saluran dan forkit pemisahan dikawal oleh mekanisme kam untuk memastikan pemisahan kertas tisu dilipat yang stabil pada laju tinggi.

4. Ia menjalankan operasi berbeza dengan mesin bungkusan, meninggalkan kedudukan beg kosong tertentu untuk troli penyediaan mesin bungkusan supaya kertas tisu yang tidak baik dibungkus boleh dengan mudah dipilih semula untuk dibungkus semula, mengurangkan kerugian.

5. Berdasarkan ketinggian lorong pemberian makanan pada mesin pengemas, mesin ini dirancang secara keseluruhan dengan pelat penyangga tebal 18mm dari depan ke belakang, membuat struktur menjadi rasional dan lebih kaku.

6.Menggunakan pengesan pintar untuk mendeteksi kertas longgar, kertas putus, kertas hilang, dan penyumbatan kertas. Jika terdapat gangguan, mesin akan mematikan dirinya secara automatik sementara lokasi gangguan dipaparkan di panel operasi. Untuk membawa mesin kembali kepada operasi normal, mudah untuk menyelesaikan masalah mengikut arahan di panel.

II.WD-HT-PM200 Penuh Automatik Mesin Pengemas Tisu

Pengenalan Mesin:

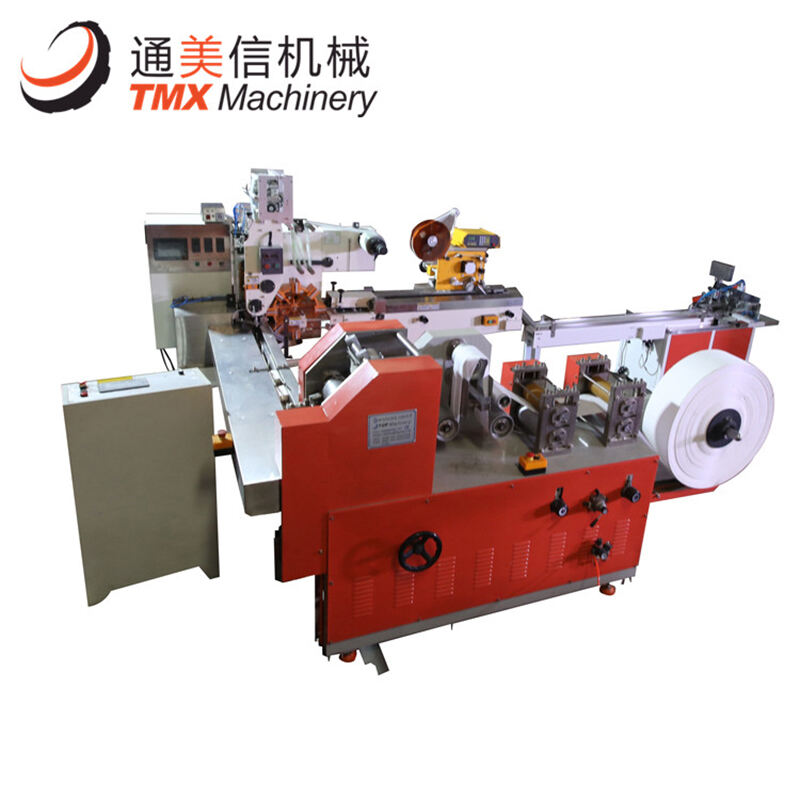

Mesin ini menggunakan filem plastik pengemas untuk membungkus tisu kerut piawai, tisu kerut mini, objek segi empat tepat, seperti yang ditunjukkan dalam gambar di atas.

Fungsi dan Ciri-ciri:

1.Seluruh operasi dikawal oleh PLC, skrin sentuh besar dan motor langkah.

2.Dilengkapi dengan sistem penjejakan dan alarm masalah automatik.

3.Sistem penjejakan fotoelektrik dengan ketepatan tinggi.

4.Pemukulan sinkron untuk pembukaan kemasan filem kertas handuk yang membolehkan konfigurasi peranti pemukul automatik dengan pelbagai bentuk pembukaan.

5.Huruf seperti tarikh pengeluaran dan nombor batc boleh dicetak secara automatik dan disesuaikan ke atas dan bawah kepada kedudukan optimum.

6.Pengeleman sinkron pita pembukaan untuk kemasan luar membawa kepada pengurangan kos tenaga kerja lebih lanjut.

III.Mesin Paking Kemasan Luar Jenis Bar Tisu Penuh Automatik

Ciri utama:

Mesin ini disambungkan dengan mesin kemasan automatik tunggal, hanya memerlukan seorang pekerja untuk operasi.

Dilengkapi dengan lipatan automatik, garis, penyampaian, sudut dan pengeleman.

Pengawal Setia Program (PLC) mengawal keseluruhan mesin, dengan panel kawalan jenis Butang Sentuh.

Kawalan berhenti mendadak / Suspend kawalan, Kawalan Keselamatan Elektrik dan pneumatik.

Mesin ini boleh membuat tisu panjang / tisu mini, boleh disesuaikan oleh roda tangan.

Boleh dikemas dalam 2 lapis atau 3 lapis dengan 10, 12, 15, 18 beg.

Data Teknikal bagi Mesin Tisu Wajah Mini / Pocket dengan pemindahan automatik

| Kelajuan melipat |

700-800pcs/min |

| Lebar bahan |

420mm |

| Diameter Maksimum bahan |

1200mm |

| Saiz produk jadi |

L:72-100mm x W:52-54mm |

| Penggoresan |

Besi kepada getah; besi kepada besi (perlu pesan) |

| sistem vakum |

Pump vakum jenis kitaran dengan 6.5kw |

| Mengira |

10pcs |

Data Teknikal Mesin Pembotolan Keratan Kepala Sepenuhnya Automatik

| Model |

WD-HT-PM200 |

| Saiz beg (mm) |

L70-110 W50-55 H22-28 |

| Keratan kepala kertas piawai |

Spesifikasi: 106mm *53mm *26mm, bilangan: 10 keping |

| Keratan kepala kertas mini |

Spesifikasi: 72 mm*53mm*26mm, bilangan: 10 keping |

| Dimensi Filem Pembotolan (mm) |

Keratan kepala kertas piawai: 150mm Keratan kepala kertas mini: 116 mm |

| Kapasiti (Pakej/minit) |

25-90 |

| Dimensi (P×L×T)(mm) |

3660×2750×1920 |

| Tekanan udara (mpa) |

0.3-0.4 |

| Berat keseluruhan (kg) |

1500 |

| Bahan Pembungkusan |

CPP、PE、PE/CPP、PT/PE dll Filem Penyegelan Dua Sisi |

| Kuasa mesin elektrik utama |

1. 1kw |

| Kuasa keluaran dan segel sisi unit elektrik |

0.18W |

| Kuasa yang menghasilkan pembarisan mesin |

3.4kw |

| sokongan kuasa |

380V, 50Hz (Untuk rujukan anda, bergantung kepada keadaan kuasa di tempat anda) |

Parameter Teknikal Mesin Pem bungkusan Paket Jenis Bar Tisu Sepenuhnya Automatik

| Model |

WD-HT-TB380A |

| Saiz produk jadi (perlu dipesan) |

Baik jenis piawai mahupun mini, 2 lapis atau 3 lapis (tetapi perlu mengesahkan panjangnya) |

| Voltan kuasa |

380V, 50Hz |

| kelajuan pembungkusan |

12-15pa/m |

| Kuasa |

2.6kw |

| Air diperlukan |

0.5 Mpa (disediakan oleh pelanggan) |

| Berat mesin |

1500 kg |

| Saiz keseluruhan |

3800mm×3100mm×1900mm(P×L×T) |

Contoh produk jadi: