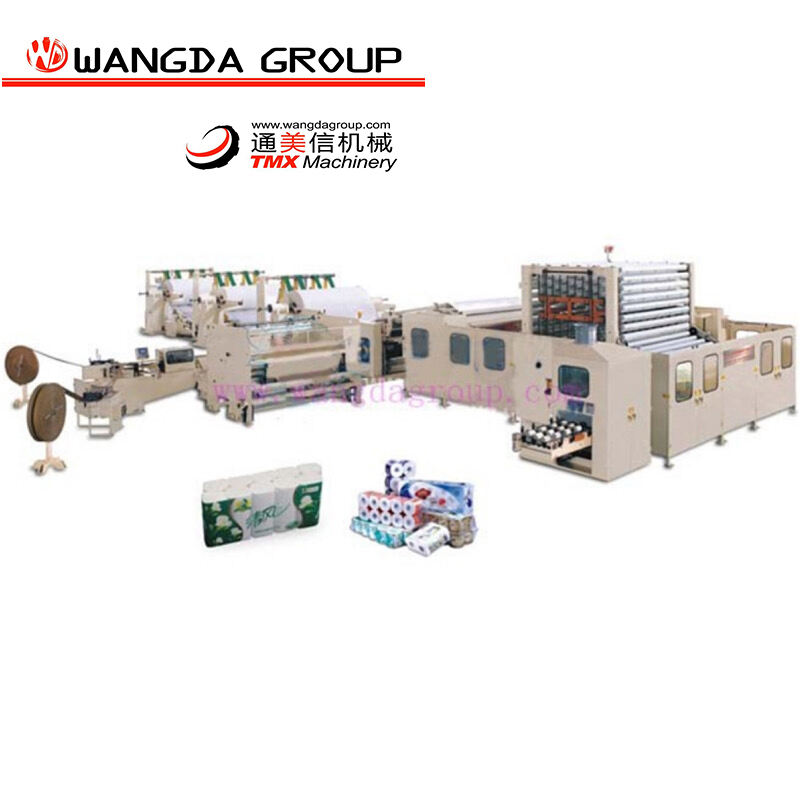

Streamlining the manufacturing process for bathroom essentials

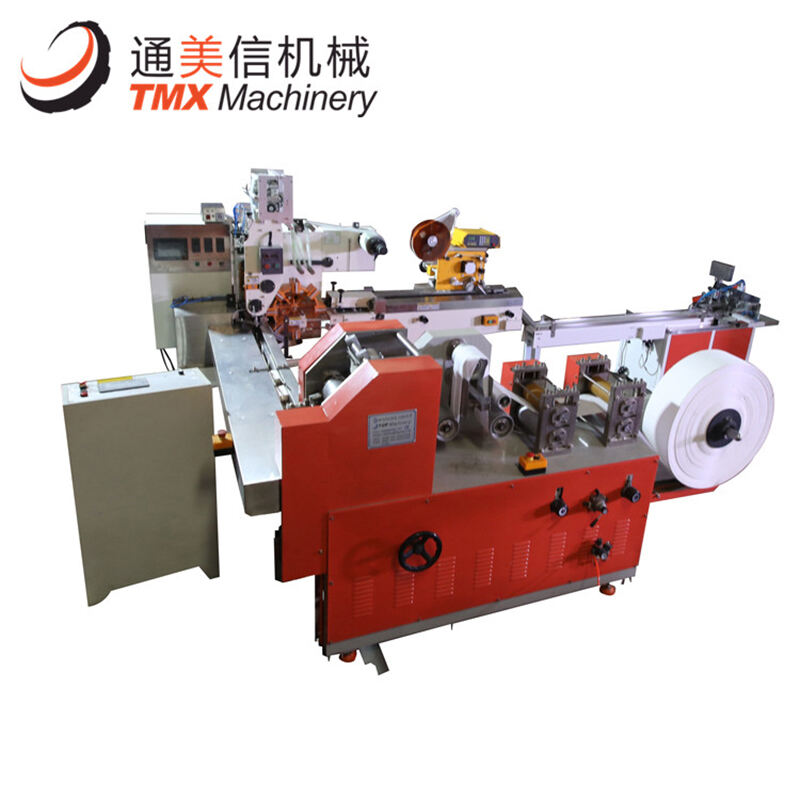

A significant part of that is the paper-making machine. This turns the puppy pulp into something of a slurry and coat this for various proportions to help photographic paper base referred as wire fabric. This is where a wire mesh (one of the key parts to get rid out excess water pulp) pulls here and there, leaving only super-fine thin sheet

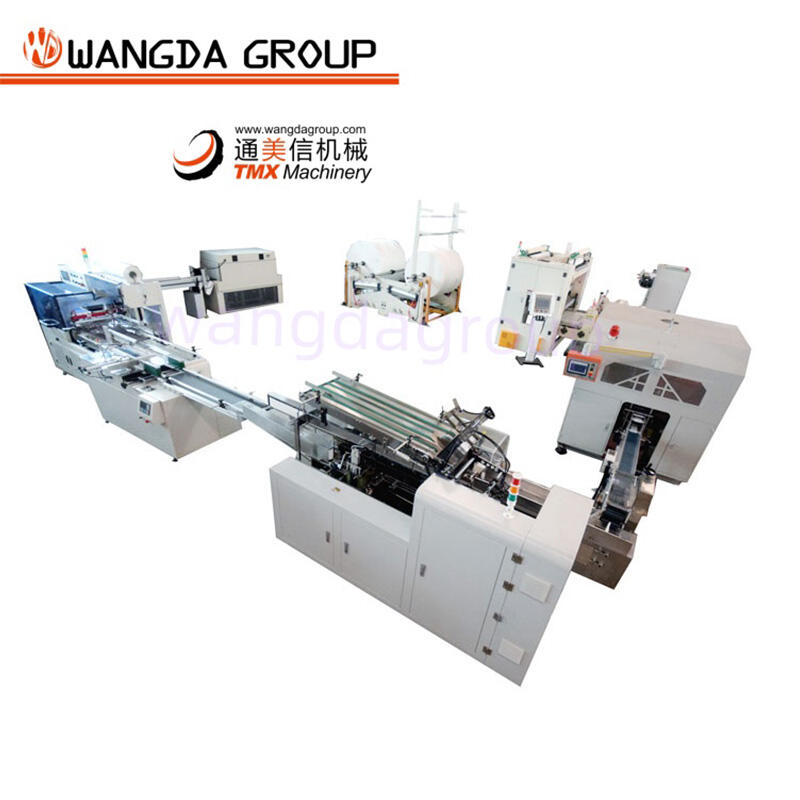

After the water is drained, this now loose material goes to a huge flat-bed area (think an industrial sized pasta roller and conveyor belt), where it has most of its retained water pressed out. This long sheet is loaded into a second machine where it shears down to size and winds the cuts around a spindle. Then we are left with a completed roll of tissue paper soon to be packed and shipped off to stores.