How New Machines are Changing Toilet Paper Production

New lumber to manufacture few key products in making toilet paper. These are primarily made from wood pulp or recycled paper. This mix is thick and it feels like paper pulp now, made up of fibers held together with tones of puffer semi-permeable water. The bleached paper pulp is then washed and cleaned after mixing to give it a white color. This is an essential step to keep the toilet paper clean so that you could use it without any worry.

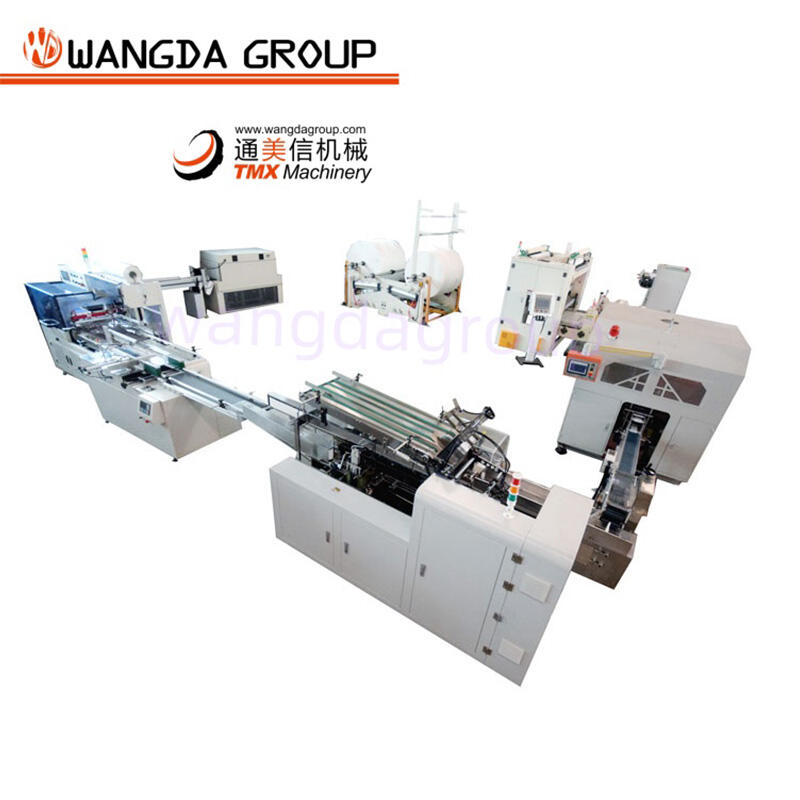

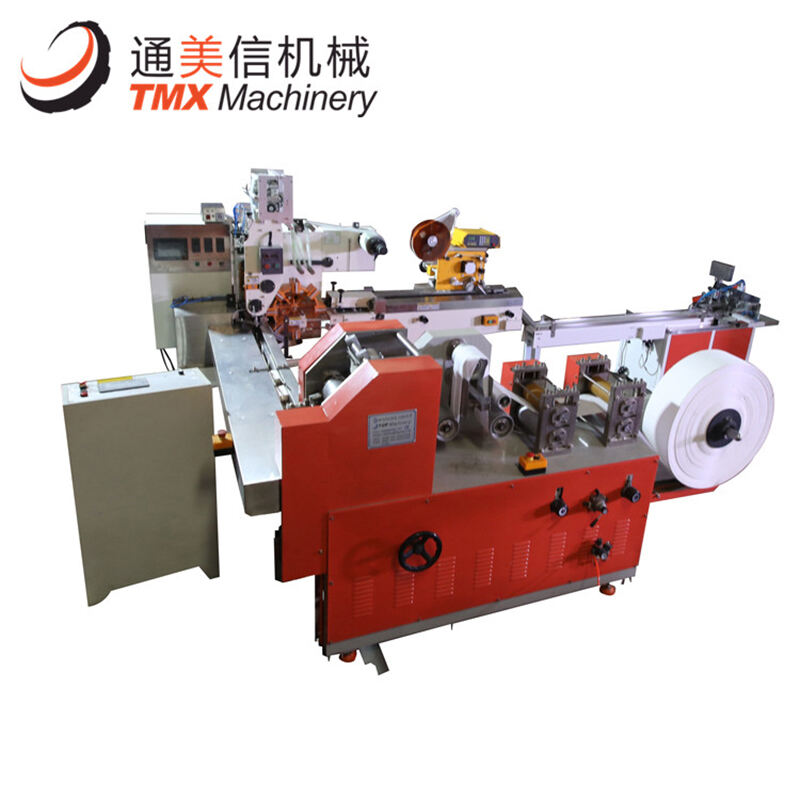

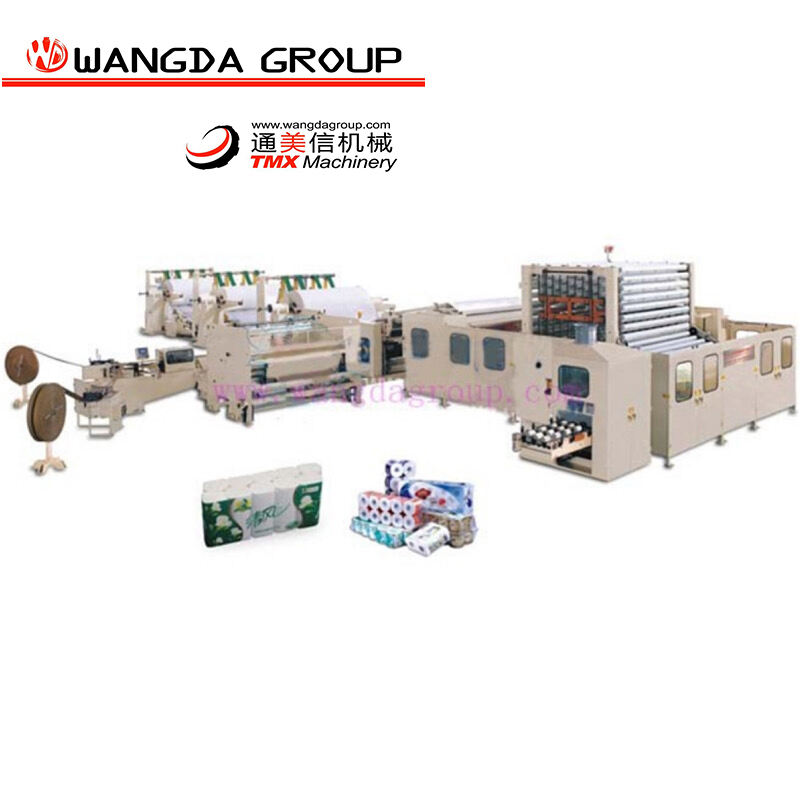

Then the paper pulp is evened out on a long conveyor belt with help of a special type machine called Wangda Industrial toilet paper manufacturer machine. The decortication or dharma machine is very important because it helps to remove excess water from the pulp. Then the paper is sent through hot rollers, which dry it and give a very smooth finish. This is an important process because it ensures domesticating to build the hoe, we all love in toilet paper.