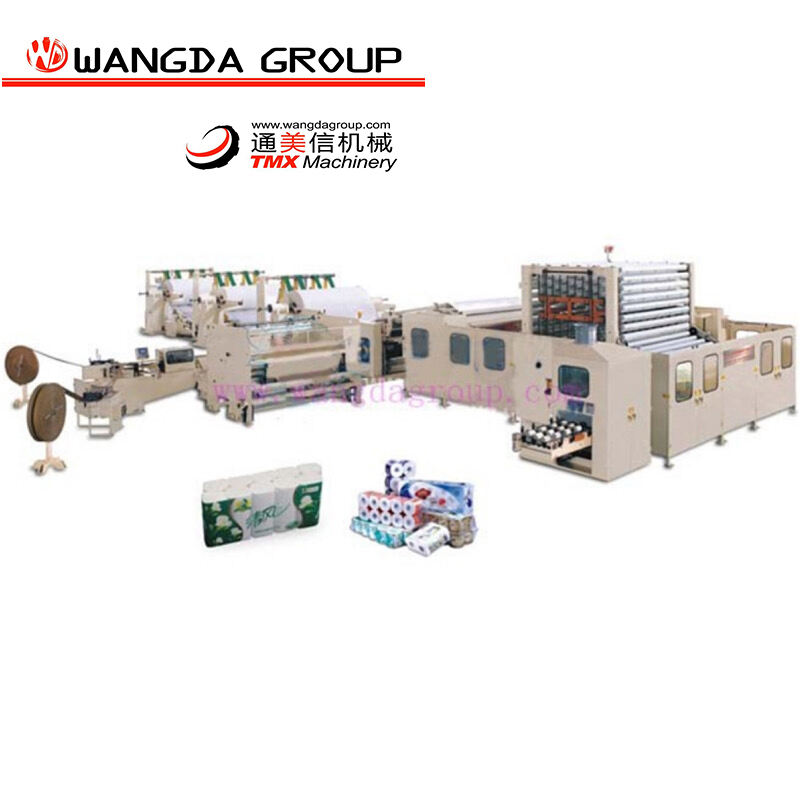

Efficiency and quality meet in the toilet tissue making machine

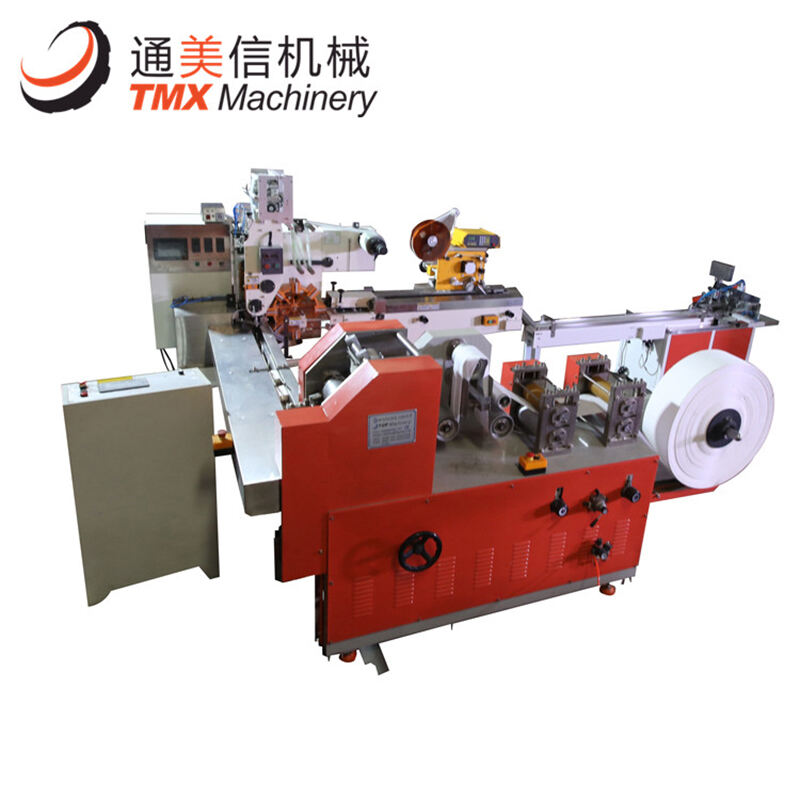

Wangda Industrial The Wet End, Explained First Now, the real magic takes off. This pulp slurry is then fed into the machine, in an area called the ‘wet end,’ where water and raw materials (like tree fibers + recycled paper) are mixed together to get sticky mush-like substance we call it Pulp. Pulp is the raw material used for making paper. The pulp, must be cleaned first of any dirt or impurities before being able to manufacture toilet paper. So, the product is free from germs and unadulterated. The pulp continues to the next part of machine. tissue paper making machine in the press section, extra water is squeezed out from pulp to form a paper sheet named "wet-pressed tissue. "

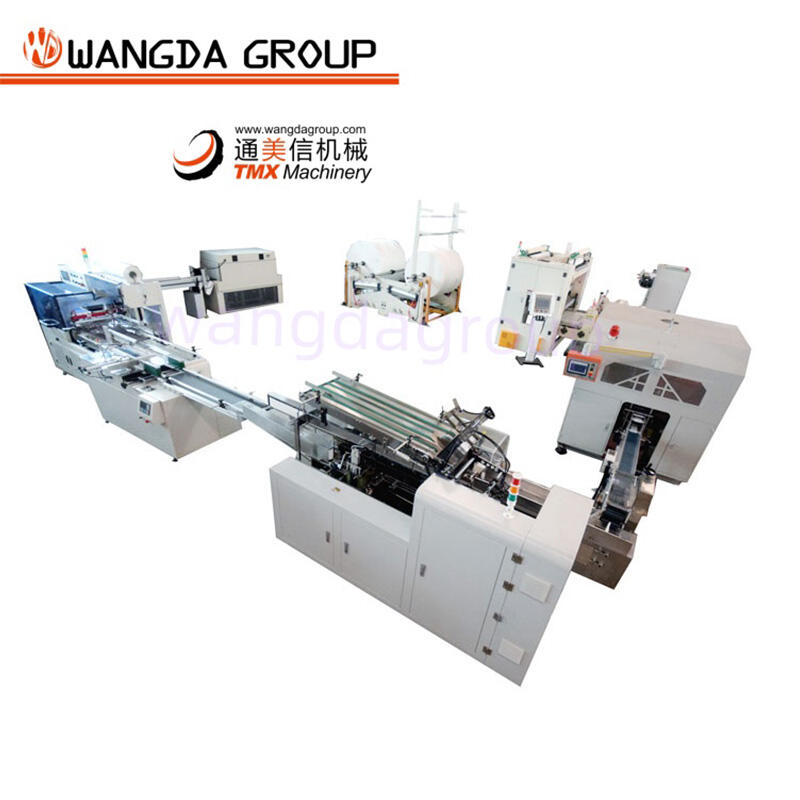

After the wet-pressed tissue is made, it goes to dry end of paper machine. The tissue is dried with hot steam. This is necessary in order to completely dehydrate the tissue and be usable. Then a piece of machinery is used to make the tissue smooth and even after which it keeps moving for further processing. It is a necessary step because who likes prickly toilet paper! Then, the tissue gets cut into smaller sheets and rolled up for us to purchase.